A brand new open-source software program package deal developed by Monash College researcher Julian Ceddia goals to considerably streamline the examine of supplies utilizing scanning tunneling microscopes (STMs).

The software program, named Scanbot, automates the time-consuming probe optimization and information acquisition processes important for STM experiments, serving to to speed up 2D supplies analysis by enabling detailed investigation after the STM tip has been routinely optimized and sharpened.

“We hope that Scanbot will profit STM labs world wide and characterize a significant step in the direction of full automation of STM experiments,” says A/Prof Agustin Schiffrin, additionally at Monash.

Remodeling supplies analysis with STM automation

Exploring and characterizing the atomic panorama of surfaces has turn into a basic pursuit in fashionable science. STMs are among the many strongest instruments that permit scientists probe and work together with the world at this unimaginable scale, offering photographs and spectroscopic information that allow us to look into the quantum realm and see how supplies behave on the atomic degree.

STMs work by scanning a probe, sharpened all the way down to a single atom, throughout the floor of a cloth whereas monitoring an electrical present. This present carries all the knowledge vital to construct up atomic-scale photographs of the floor.

Nevertheless, attaining these breath-taking photographs is not any simple feat. A probe sharpened to the scale of a single atom is extraordinarily fragile, and even the slightest contact with one other atom, molecule, or particles can drastically alter the probe’s effectiveness, requiring researchers to spend appreciable time optimizing the instrument to make sure it captures high-quality, dependable information.

Introducing Scanbot

Researchers at Monash College, led by Julian Ceddia, have developed a dependable method to automate this STM optimization course of, ensuing within the creation of Scanbot—a freely obtainable open-source software program package deal.

The analysis paper is revealed within the Journal of Open Supply Software program.

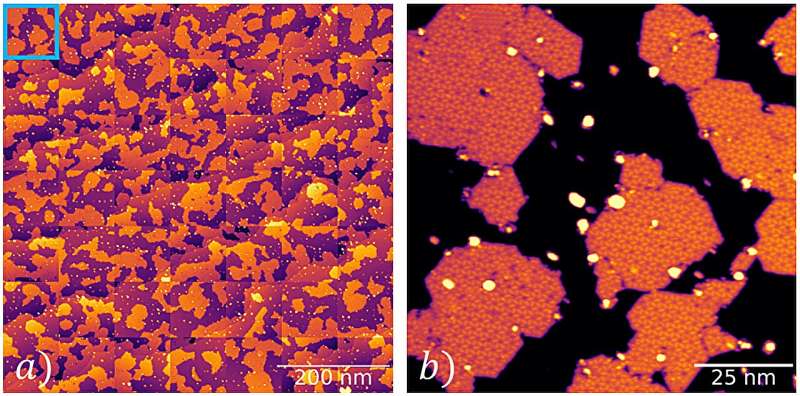

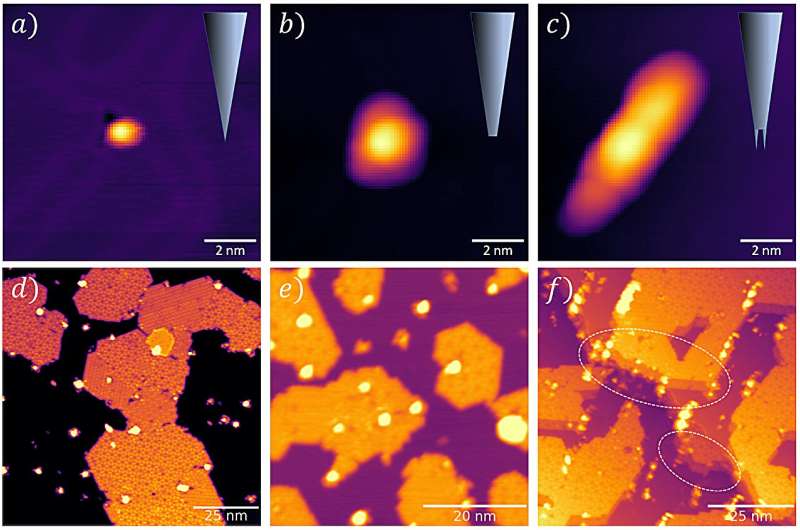

Ceddia explains {that a} revelation got here to him after getting uninterested in the hours he routinely wasted optimizing and sharpening the STM tip simply to get significant information. “After numerous hours spent fine-tuning the STM throughout my Ph.D., I found that the standard of the probe could possibly be simply quantified by imaging imprints that it leaves behind after being poked just some angstroms into the floor.”

These imprints carry details about the association of atoms on the tip of the scanning probe and are key to predicting how good the information can be earlier than buying it. “Principally, sharper suggestions go away behind smaller imprints. So, Scanbot automates the method by repeatedly urgent the tip into the floor till the imprint exhibits that the tip is sharp sufficient for high-quality imaging,” Ceddia explains.

This easy method to “tip shaping” avoids most of the challenges related to utilizing machine studying for comparable duties. “As an alternative of coaching an AI on huge quantities of labeled information to acknowledge high-quality photographs, Scanbot makes use of easy algorithms to measure the scale and symmetry of the probe apex primarily based on the imprints it leaves,” provides Dr. Benjamin Lowe, a key collaborator on the challenge.

However Scanbot’s capabilities prolong past simply tip shaping. It additionally automates widespread information acquisition methods, comparable to pattern surveying, making STMs simpler to function general. “My aim with Scanbot was to make STM extra accessible and user-friendly,” says Ceddia. “That is why I invested plenty of time into designing an intuitive consumer interface and writing complete documentation.”

Trade recognition and affect

Scanbot’s potential was aptly captured by former Monash College researcher Jack Hellerstedt, who additionally made important contributions to the challenge, “Scanbot has the heretical potential to get-up-and coming floor scientists serious about the information as a substitute of clicking the button.”

The trade is already taking discover of Scanbot’s capabilities. SPECS, a number one firm in STM system management, not too long ago contacted Ceddia after discovering Scanbot.

“Receiving an electronic mail from SPECS asking to incorporate hyperlinks to Scanbot of their documentation was extremely encouraging,” Ceddia displays. “It is a sturdy validation that our work might genuinely make a distinction in the best way STMs are operated.”

Extra info:

Julian Ceddia et al, Scanbot: An STM Automation Bot, Journal of Open Supply Software program (2024). DOI: 10.21105/joss.06028

Quotation:

Open-source software program helps streamline 2D supplies analysis with scanning tunneling microscope automation (2024, September 9)

retrieved 10 September 2024

from https://phys.org/information/2024-09-source-software-2nd-materials-scanning.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.