Sustaining heavy gear property, equivalent to oil rigs, agricultural combines, or fleets of autos, poses an especially complicated problem for world firms. These property are sometimes unfold throughout the globe, whereas their upkeep schedules and lifecycles are usually decided at a company-wide stage. The failure of a key element can lead to tens of millions of {dollars} of income losses per day, in addition to downstream impacts to clients. That’s why many firms are turning to Generative AI to realize insights from the terabytes of information these property generate day by day. These insights may also help obtain important time and price financial savings by forecasting outages and bettering the Upkeep, Restore, and Operations (MRO) workflow.

Kubrick, a Databricks consulting companion, works with purchasers throughout industries to revolutionize their skills to foretell and reply to heavy gear upkeep necessities. By leveraging Kubrick and Databricks applied sciences and experience, these organizations are bettering outcomes for companies throughout the worth chain, positioning themselves for market management and mitigating regulatory threat.

Getting MRO Again in Gear

When the COVID-19 pandemic introduced the world to a standstill, the hyperlinks connecting our manufacturing provide chains have been damaged because of closed borders and furloughed workforces. Unsurprisingly, the transport and logistics sector was the primary to be impacted by the disruptions and face monetary losses; vitality, agriculture and manufacturing then skilled a follow-on impact.

Nonetheless, companies throughout the provision chain are actually getting ready to surpassing pre-pandemic enterprise ranges, as clients have adopted new spending (and journey) habits. This dramatic restoration brings its personal set of challenges, as industries equivalent to airways, freight, and logistics face provide constraints because of manufacturing delays from OEMs – a ripple impact from when manufacturing shut down in the course of the pandemic. In these hypercompetitive industries, minimizing restore delays and maximizing automobile or equipment functionality is important for staying worthwhile.

Many companies that depend on heavy gear wish to next-gen know-how to realize the better effectivity required to stay aggressive. The important thing to the profitable implementation of information and AI in MRO is to first determine the use instances that drive tangible worth after which to create a roadmap that reduces prices and boosts income. Kubrick, in partnership with Databricks and Neo4j, has designed an revolutionary answer that enhances technical operations throughout the upkeep lifecycle.

The Problem and Alternative of MRO & Provide Transformation

For companies with heavy gear or automobile fleets, upkeep prices are a pivotal a part of the stability sheet, usually figuring out the result of their backside line. It’s reported that upkeep prices are the third highest outlay for airways, freight, and delivery firms, after gasoline and worker salaries. In the meantime, the MRO business at massive is ready to develop by $50 billion within the subsequent few years, as companies compete for restricted instruments and sources.

Nonetheless, upkeep spending has important potential for optimization with knowledge and AI instruments, making it a major focus for companies using heavy gear to considerably alter their revenue margins and income. Areas for enchancment with knowledge and AI embrace:

- Velocity and accuracy: Present knowledge logging processes can take as much as 24 hours.

- Guide knowledge retrieval, analytics, and reporting: Guide logging and evaluation of upkeep occasions can create inaccuracies in figuring out the root-cause points, resulting in failed resolutions that enhance prices and waste technicians’ time.

- Siloed knowledge: Lack of connectivity between knowledge sources throughout the MRO lifecycle limits visibility into interrelated challenges within the provide chain, upkeep points, decision documentation, and regulatory codes.

- Aggressive threat: With out superior analytics, companies battle to reply rapidly and anticipate points.

A good portion of upkeep work is concentrated on figuring out defects, irregularities or malfunctions that may have an effect on a automobile or gear’s security and efficiency. Typical processes for figuring out and addressing these defects are guide and sluggish, making it tough to foretell and sort out challenges.

The problem is compounded throughout the MRO lifecycle, leading to difficulties with defect prognosis and backbone. Points embrace:

- Delays in processing the logging of upkeep points (as much as 24 hours)

- Restricted correlation with the provision chain for elements availability

- Lack of visibility to upkeep engineers’ availability for addressing recognized points.

- Little correlation between a upkeep occasion and its technical answer. Engineers should manually search by way of intensive documentation to search out decision necessities, slowing response time. This can lead to resolutions which might be misaligned with the difficulty, including pointless complexity/value.

- Restricted historic data to anticipate resolutions.

This combine of things means responding to points can take hours to days, leading to diminished utilization of heavy gear, equivalent to delayed freight delivery or grounded passenger plane. Finally, the associated fee to the underside line for inefficient restore options may restrict top-line income.

In the meantime, extremely guide knowledge assortment and evaluation additionally prolong the time wanted to fulfill regulatory physique necessities. As the general public eye sharpens its give attention to industries experiencing extremely publicized upkeep failures, equivalent to airways and vitality producers, regulatory compliance has by no means been extra vital.

These challenges additionally present a possibility: Slicing-edge knowledge and AI capabilities can present higher insights, predict upkeep, and provide chain disruptions, and allow quicker responses, maximizing fleet utilization and avoiding expensive unplanned outages.

The Finish-to-Finish Answer

Kubrick has developed a compound AI system that leverages the Databricks Information Intelligence Platform to seamlessly rework uncooked knowledge into useful enterprise insights, addressing the multitude of interconnected challenges within the MRO lifecycle. The answer is powered by a data graph that interfaces with a sequence of dashboards and a upkeep chatbot to ship insights to finish customers. At a excessive stage, it’s comprised of:

- Supply Methods: Information from the upkeep database of kit/automobile elements and stock is mixed with related stay and historic knowledge, equivalent to defects, work orders, out-of-service occasions, in addition to related regulatory/upkeep codes and manuals.

- Ingestion: Instruments equivalent to Azure Information Manufacturing unit (ADF), Fivetran, and so forth., are employed to ingest the info

- Storage: Azure Information Lake Storage (ADLS) Gen 2 on Microsoft Azure is used for storage

- Information Processing: All unstructured, semi-structured and structured supply information are processed on the Databricks Information Intelligence Platform utilizing Delta Reside Tables (DLT) and streaming jobs to construct bronze, silver, and gold tables in Unity Catalog. Unity Catalog ensures knowledge governance, integrity, lineage, and high-quality monitoring by way of established requirements for every medallion structure stage. The Neo4j Apache Spark™ Connector hyperlinks the Databricks Platform with a data graph, seamlessly integrating gigabytes of ingested knowledge from Unity Catalog to create tens of millions of nodes and edges which might be written on to the graph. These nodes and edges are relationships between defects, elements, stations, upkeep engineers, and so forth. Lastly, the unstructured textual content of the related restore guide is embedded into Databricks Vector Seek for retrieval-augmented era (RAG) utilizing LLMs.

- Information Visualization: The data graph helps a number of dashboards, which supply views for senior stakeholders on urgent upkeep points, historic fleet well being and present work orders, out-of-service occasions, and defects.

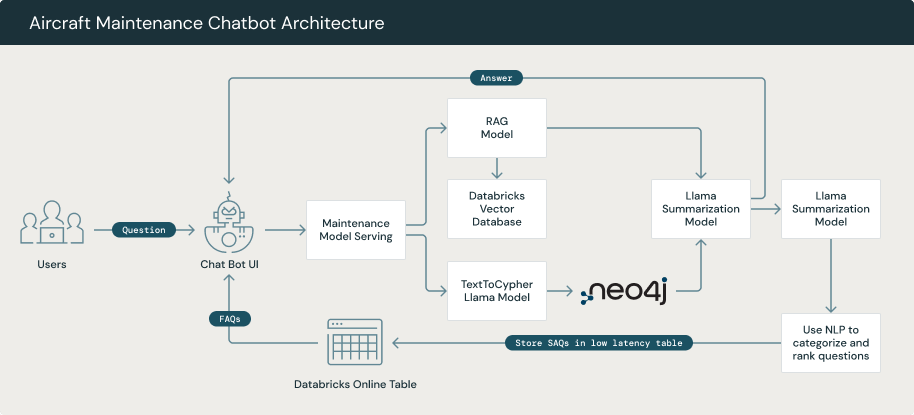

- Generative AI: Databricks Mosaic AI is used to construct an end-to-end compound AI system. Mosaic AI Mannequin Serving is used to host a fine-tuned Llama 3 mannequin for text-to-cypher era and a base Llama mannequin that powers a RAG-enabled chatbot, a ResultsToText mannequin and a generator mannequin for summarization. When a person question is entered into the chatbot, the suitable mannequin queries the data graph and/or Mosaic AI Vector Search with the generator mannequin summarizing each responses.

The Databricks Information Intelligence Platform ensures that knowledge is processed effectively, whereas fashions are served in a safe setting. Kubrick’s purchasers profit from a sturdy and scalable answer that decreases their upkeep prices.

Leveraging Generative AI for Upkeep Options

LLMs present a singular and cutting-edge alternative to distill sophisticated info into easy-to-understand, human-readable textual content. Kubrick’s purpose-built structure contains a chatbot designed particularly for technicians, serving to them save time and offering fuller context when resolving defects. Usually, a chatbot has a number of endpoints to reply several types of questions; this gear upkeep chatbot has two retrieval fashions, every connecting to a separate endpoint.

- Neo4j Endpoint: The primary retrieval mannequin, TextToCypher, fetches the gear knowledge from a Neo4j graph database. This element of the mannequin leverages a Llama 3 mannequin that’s pre-trained on cypher knowledge, for simpler text-to-cypher conversions. By using Databricks Mosaic AI, the mannequin is deployed as an endpoint inside Databricks, which we then name within the DsPy perform. DsPy supplies the advantage of easy and efficient immediate engineering. After acquiring the generated cypher from the endpoint, the mannequin executes this cypher code on our Neo4j database. The ensuing knowledge is then handed to the ResultsToText mannequin, which converts it right into a readable format for end-users. This output supplies context concerning the defect, equivalent to the connection between the defect, half, station, upkeep engineer, and so forth. and offers extra perception to upkeep engineers.

- RAG Endpoint: The second retrieval mannequin is one other Databricks endpoint that employs a RAG-enabled chatbot. The chatbot is linked to a Mosaic AI Vector Search index containing upkeep manuals and different written paperwork related to the automobile or gear. The perception supplied is data concerning the gear, its elements, and greatest practices documented within the guide.

These endpoints each have clear use instances. For instance, when the upkeep chatbot is requested a query a few particular piece of kit or automobile, it can question the TextToCypher endpoint, as this query will be answered utilizing the data graph. For a query about laws on elements, the RAG-enabled endpoint shall be queried, because the guide’s textual content is required to reply this query.

Nonetheless, if a upkeep employee asks concerning the steps to repair a selected challenge on a chunk of kit or automobile, the guide might have instructed steps, however there may be helpful info within the graph database about earlier steps taken on that piece of kit or the same one which confronted the identical challenge. On this case, the chatbot would ship the person’s query to each fashions to assemble complete info. Then, as soon as the related info is obtained from each sources, one other endpoint combines the outcomes right into a readable and helpful format for the top person.

This course of orchestrates a number of endpoints to ship probably the most correct insights to the upkeep engineers and reduce the latency of calling a number of endpoints. First, it sends the queries to the endpoints concurrently since neither endpoint depends on the opposite’s output, permitting each to run concurrently. Second, it creates a cache to test if a query has been beforehand requested and answered accurately and returns the cached outcomes from it, thus decreasing time on future queries.

Caching methods for FAQs will be carried out utilizing Databricks. Step one is to gather and rank FAQs saved in Delta tables, utilizing NLP methods to categorize and rank questions primarily based on frequency and relevance. Then, ranked FAQs are saved within the on-line desk, up to date often to mirror modifications in person habits and new questions, and built-in into the UI to permit customers to view probably the most regularly requested questions per class. Lastly, technicians can evaluate related FAQ classes within the UI earlier than submitting a brand new query, decreasing duplicate questions, and bettering the person expertise.

The mannequin’s efficiency is evaluated in two crucial methods. First, one other LLM acts as a decide for all modules that generate human-readable textual content. This LLM-as-a-judge mannequin ensures that the generated responses precisely reply the query, keep away from hallucinations and match the anticipated output format. The second analysis methodology includes the TextToCypher module. Since this mannequin generates code somewhat than human-readable textual content, it can’t be evaluated by one other LLM in the identical approach. As an alternative, it makes use of a customized analysis perform in Databricks Managed MLflow. This perform runs the generated code on Kubrick’s database to confirm its performance after which compares the outcomes to these produced by the bottom fact code. A match ends in a constructive analysis, whereas a discrepancy ends in a detrimental one.

Conclusion

By leveraging the Databricks Information Intelligence Platform, Kubrick initiatives that they’ll be capable of scale back heavy gear upkeep prices for purchasers by tens of millions of {dollars}, with estimates exceeding 9 figures throughout a three-year rollout. The worth of Kubrick’s answer derives from making use of Databricks instruments equivalent to Delta Reside Tables (DTL), streaming jobs, Unity Catalog, and Mosaic AI, making the sum of its elements all of the extra environment friendly and highly effective. By working carefully with purchasers to know and handle their upkeep challenges, Kubrick is happy to be driving large-scale transformation within the MRO course of. To be taught extra about Kubrick’s supply and resourcing capabilities in partnership with Databricks, contact [email protected]