A Japanese analysis group led by Professor Minoru Osada from the Institute for Supplies and Programs for Sustainability (IMaSS) at Nagoya College has pioneered a way for the high-speed, large-area deposition of two-dimensional (2D) supplies, together with oxides, graphene oxide, and boron nitride. This revolutionary approach, referred to as the “spontaneous built-in switch methodology,” was found by likelihood; nonetheless, it guarantees to revolutionize the manufacturing of nanosheets.

The analysis findings had been printed within the journal Small.

Nanosheets are characterised by being only some atoms thick. On account of their excessive floor space relative to their quantity, these sheets exhibit distinctive digital, optical, mechanical, and chemical properties. Nanosheets stand to probably revolutionize trendy electronics and supplies science.

Historically, strategies like chemical vapor deposition (CVD) and the Langmuir-Blodgett (LB) approach have been employed for nanosheet fabrication. Nevertheless, these strategies have important obstacles to their use, together with difficulties in attaining uniform, large-area deposition and problems within the substrate switch course of.

Of their quest for a more practical deposition know-how, Osada’s group found a captivating phenomenon utterly by likelihood: when nanosheets get moist, they spontaneously align themselves on the floor of water, forming dense movies inside a mere 15 seconds. This course of, termed the “spontaneous spreading phenomenon,” instructed a more practical deposition know-how.

The group examined this system by dropping a nanosheet solvent combination onto the water floor. On account of ethanol’s greater volatility in comparison with water, it evaporates extra quickly, making a focus gradient on the floor.

Areas with extra ethanol evaporation have greater floor stress than these with greater ethanol focus. This distinction in floor stress causes fluid to maneuver from areas of decrease to greater stress, producing convection currents. These currents information the nanosheets throughout the answer, inflicting them to rearrange in a extra ordered and dense formation on the water floor.

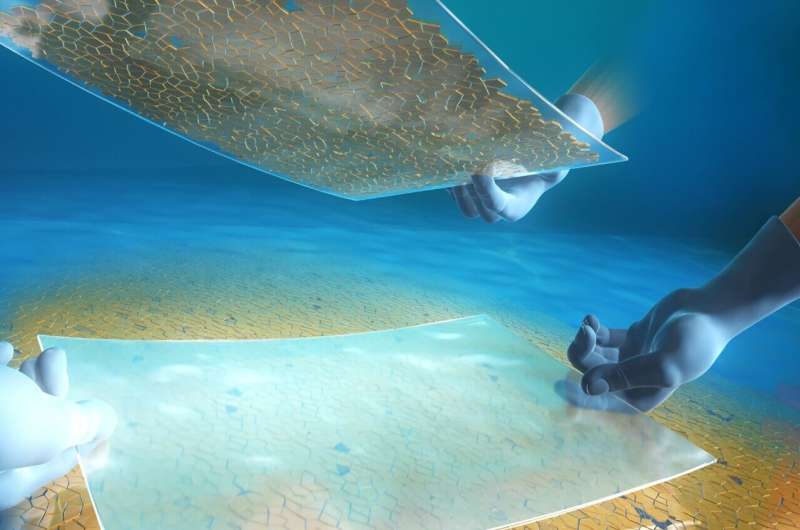

“The nanosheets spontaneously align and pack intently collectively, very like ice floes coming collectively on the floor of water,” Osada mentioned. “This managed alignment is crucial for creating uniform and high-quality nanosheet movies. The ensuing nanosheet movie can then be simply transferred onto a substrate, finishing the deposition course of in as little as one minute.”

This methodology not solely simplifies the manufacturing course of but additionally opens the door to producing multilayer thick movies with 100 to 200 layers—one thing that has been tough to attain with standard strategies like CVD and LB. Atomic power microscopy and confocal laser microscopy confirmed that the nanosheet movies produced via this system had been extremely uniform, with densely packed nanosheets organized like items of a jigsaw puzzle.

The group had been stunned by the flexibility of this system, making use of it efficiently to numerous nanosheet compositions and buildings, permitting for the manufacturing of large-area movies on substrates of various shapes and supplies.

“The multilayer movies fabricated by this know-how exhibit wonderful properties as purposeful skinny movies. They could possibly be utilized in clear conductive movies, dielectric movies, photocatalytic movies, corrosion prevention movies, and thermal shielding movies,” Osada mentioned.

Along with its technological benefits, Osada emphasised the environmental advantages of this methodology, saying, “This know-how is anticipated to change into an vital environmentally pleasant eco-process as a result of it permits skinny movie manufacturing on numerous substrates at room temperature and in an aqueous answer course of, with out the necessity for vacuum film-forming gear or costly instruments, that are frequent in standard skinny movie processes.”

Extra data:

Yue Shi et al, Ultrafast 2D Nanosheet Meeting through Spontaneous Spreading Phenomenon, Small (2024). DOI: 10.1002/smll.202403915

Journal data:

Small

Supplied by

Nagoya College

Quotation:

Excessive pace, large-area deposition nanofilm manufacturing potential with new approach (2024, August 22)

retrieved 26 August 2024

from https://phys.org/information/2024-08-high-large-area-deposition-nanofilm.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.